Many people have heard of 3D printers, but many aren’t sure what it is exactly. After all, you can think of them as the 21st century’s answer to the stone age’s carving knife. These amazing machines create three-dimensional objects from a digital blueprint. This process is called additive manufacturing. 3D printing has been around since the mid-1980s but was not widely adopted until relatively recently.

Today, it is being used in industries such as manufacturing, architecture and medicine to produce precise, custom parts that would be too expensive or time-consuming to manufacture using traditional methods. This article will provide you with an elementary overview of this exciting technology.

/img/iea/JYG0Z1Aqw1/3d-print.jpg)

What is 3D Printing?

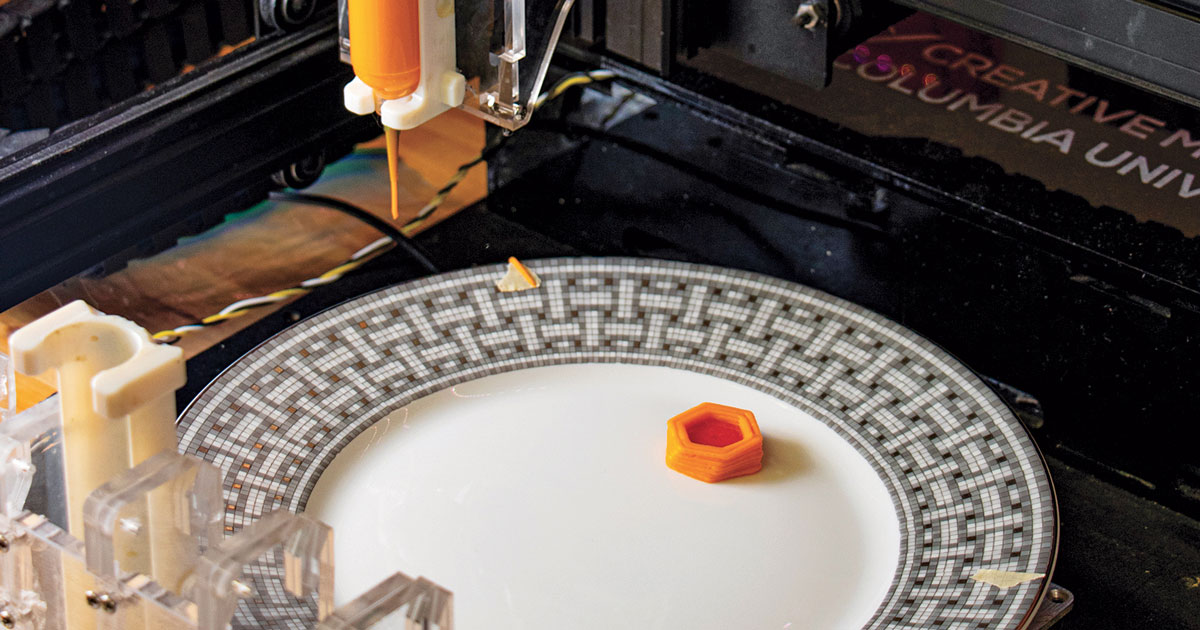

A 3D printer is a machine that creates three-dimensional objects by depositing layer by layer an exact copy of the digital design file. This process creates objects layer by layer so that no two items ever produced by the machine will be exactly the same. A 3D printer works by combining liquid resin and a fine solid powder like starch, sand or clay. When these two materials are combined they form a gooey substance that solidifies when it comes into contact with a warm print head.

The print head is a series of nozzles that dispenses the goo onto a print bed that is heated to the right temperature. The nozzles are made of a melted plastic material, allowing them to expand and contract while they spray the goo onto the print bed. The print bed is typically a plastic sheet that has a grid of fine lines printed on it. This creates a surface upon which the model is built. The model can either be a two-dimensional image or a three-dimensional object.

How does 3D Printing work?

There are multiple 3D printing methods and each has its own advantages and disadvantages. The two most common methods of 3D printing are fused deposition modeling (FDM) and stereolithography (SLA). FDM is a process that creates parts by extruding liquid resin through a print head onto a build platform. It is a relatively straightforward process that uses a special extrusion printer to create a substance that hardens when exposed to a certain temperature.

Filament is then fed through a serger to form a long continuous thread that is used as a build platform. After the build platform has been created it is unravelled and the printed part is cut off where the thread has been. SLSA is the more complex of the two methods and creates a high-resolution three-dimensional object by building layers of a liquid photopolymer model.

A UV laser is used to polymerize the liquid photopolymer model layer by layer, just like a standard printing process. The laser is kept very cold, below -200 degrees Fahrenheit, to avoid melting the model and the build platform must be kept at the proper temperature for the polymerization process to work correctly.

Popular 3D Printing Materials

As 3D printing has developed over the past few decades, a number of different materials have been used. The two most common materials are plastic and glass. Both allow the printer to create objects that are strong while also being relatively light. In addition, both materials are transparent, allowing the user to see the model layer by layer as it prints.

While there are many different plastics that can be used in 3D printing, they are typically available in only one colour since they are designed to be melted at a specific temperature. This has led to the use of second- and third-party filaments that are designed to be used at lower temperatures. Some of the most common materials used for 3D printing are:

- ABS – Polyactic Acid – An inexpensive and flexible plastic that is used in many consumer 3D printers.

- PLA – Polylactic Acid – A biodegradable plastic that is also compostable.

- HIPS – High-Performance Polystyrene – An opaque plastic used for professional printers and is recyclable.

- Nylon – Polyamide – A durable plastic used in 3D printing, but only for tough applications.

- PET – Polyethylene Terephthalate – A tough, glossy plastic used in many applications due to its strength and toughness.

- PC – Polycarbonate – A hard, transparent plastic used in many applications due to its strength and toughness.

- T-Shirt Polyester – A tough plastic used in many applications due to its strength and toughness.

How can 3D Printing Be Used in Manufacturing?

The most common applications for 3D printing are in the manufacturing industry. For example, a company might want to make a few thousand statues of their logo to place around their city or state. In this situation, they could start by designing the logo in an Illustrator file, then use 3D printing to produce a statue. The company could then place the logo on the statue or sell it to someone else. Another example would be in the field of architecture.

Architects use 3D printing for creating custom models that have to conform to strict building codes. For example, a building could be designed to have a certain amount of wind resistance and a certain amount of earthquake resistance. Architects can use 3D printing in their projects to create a model that has both of these characteristics. They can then use the model to convince authorities to allow them to build a certain way. This is just one way in which 3D printing is being used in manufacturing. There are many more.

Pros and Cons of 3D Printing

So how do you decide whether 3D printing is right for your business? First, it’s important to understand the advantages and disadvantages of the technology. These include the following:

- 3D printing has been used since the 1980s, but it has only recently become mainstream. In other words, there is a lot of potential to develop new types of 3D printers and printing materials.

- 3D printers offer very high resolution that allows for sharp details when printing models. This is very desirable in applications like architecture.

- Most of the 3D printers on the market are commercial-grade machines costing thousands of dollars. This is great for large companies that have the budget, but not for small businesses that may not have the money for a 3D printer.

- 3D printing is now being used in a variety of industries. There is a lot of potential for growth, which means it will be important for businesses to stay on top of the technology. There are a few drawbacks to 3D printing. For example, the substance used to create 3D printed models is not recyclable, so it will eventually have to be disposed of.

Conclusion

3D printing is a relatively new technology that allows engineers and designers to create models using computer files. The printer builds the model by extruding liquid resin through a print head and laying down layer by layer of the design. This process can create models in a wide variety of materials, including plastic and metal. There are a few drawbacks to 3D printing, but they don’t outweigh the benefits.