3D printers come in a variety of different types. You can get a simple, low-end plastic filament printer for as little as $100, or you can spend thousands on a fully automated industrial grade 3D printer that costs more than an automobile. The type of 3D printer you get will depend on your needs and budget. This article will explain the differences between Fused Deposition Models (FDM) and Digital Light Processing (DLP) and why one is better suited for certain tasks than the other.

What is a Fused Deposition Model?

In FDM, a plastic filament of varying colors and composition is melted and forced through a tube where it hardens onto a build plate to create a 3D model. The build plate is then submerged in a bath of liquid enamel where the color of the plastic layer is transferred to the model. FDM printers are great for producing large quantities of inexpensive 3D models for a variety of applications. They’re cheap to buy and easy to use, and they offer good speed and accuracy. FDM printers are best for producing general shapes like model cars and furniture.

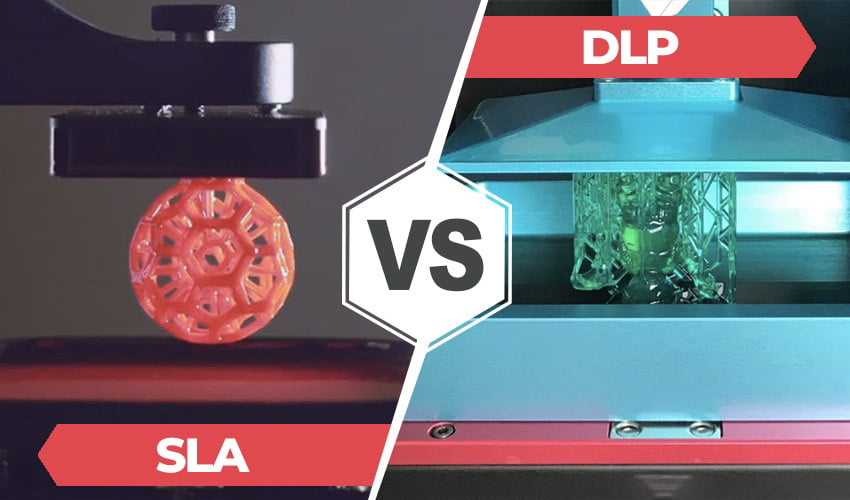

What is a Digital Light Processing?

DLP 3D printers use a semiconductor light source to project a digital image onto a piece of photo-sensitive material to create a 3D model. Unlike FDM, each layer of plastic ink is hard-edged and is not dissolved in enamel. This enables DLP 3D printers to create high-resolution models without the need for a support structure. The digital light source can be either a Xenon or Neon based lamp, which is then converted into an alternating current using a charge coupled device (CCD).

When the photo-sensitive material touched by this light is exposed to it, the electrons in the material are excited and travel to the surface, causing the material to glow. DLP 3D printers are best for creating high-resolution models, especially when it comes to engineering designs or medical imaging. Compared to FDM 3D printers, DLP 3D printing is more expensive, but the amount of time it saves on printing is astronomical.

Which 3D printer is better for printing in plastics?

Like the name suggests, a FDM 3D printer is great for printing in plastics, which is why it’s the preferred choice for manufacturers who want to produce 3D-printed injection molds. FDM printers can’t print in metals, so if you want to create metal parts, you should consider an SLM or SLS 3D printer.

A material extrusion 3D printer works with a variety of filament materials like PLA, ABS, and HIPS, and it is the best choice for printing functional parts like toys, electronics, and household appliances. An FDM 3D printer is also known as a “resin 3D printer,” and it’s the most affordable of the three types of 3D printers. You can print with a variety of materials including wood, stone, rubber, or clay.

Which 3D printer is better for printing in metals?

SLM 3D printers can print in a variety of metals, including aluminum and stainless steel, and they have the best resolution of the three types of 3D printers. SLS 3D printers can’t print in metals, and they produce quality models in both plastics and glass. SLM 3D printers are best for creating functional, high-quality products like jewelry, automotive parts, and tools. SLS 3D printers are great for making prototypes and are useful for creating models in any material.

Printable materials for a 3D printer

Depending on the kind of 3D printer you have, you may be able to print a variety of materials. If you have an SLA 3D printer, for example, you can print with a variety of UV-curable resins that enable you to print a wide range of materials, like plastics, paper, and rubber.

But if you have a fused DMLP 3D printer, you can only print with thermoplastic polymers, like polycarbonate, polypropylene, and polyethylene. Another thing to consider before purchasing a 3D printer is the size of the build area. If you want to print small models, you’ll want to look for a mini 3D printer. If you want to print large architectural models, you’ll want to look for a large 3D printer.

Which 3D printer is better for printed prototypes?

A SLM 3D printer enables users to print in metals, like all three types of 3D printers do. SLS 3D printers can also print in a variety of materials, but the resolution isn’t as high as SLM 3D printers. DLP 3D printers can produce high-quality models in both plastics and metals, but the resolution is lower than SLM and SLS 3D printers. DPL 3D printers are best for producing printed prototypes that can be tested in different environments or presented to customers. SLM 3D printers are great for creating more accurate prototypes and models in materials such as metals and glass.

Conclusion

Ready to get started on your next 3D printer project? Before you hit the buy button, it’s important to understand the differences between FDM and DLP 3D printers and how they can help with unique tasks. The most important aspect to consider when purchasing a 3D printer is what tasks you want to use it for, and that will determine which type of printer is best for you.

In general, filament-based 3D printers are cheaper, more durable, and more flexible for making a wider range of materials than DLP 3D printers. And DLP 3D printers are more suitable for large-scale production than UV resin 3D printers, but which type of 3D printer is best for you depends on your specific needs, budget, and design preferences. While it’s important to consider these factors when purchasing a 3D printer, don’t let the marketing jargon discourage you from exploring the exciting world of 3D printing. With the right 3D printing system, anyone can create almost any object imaginable.