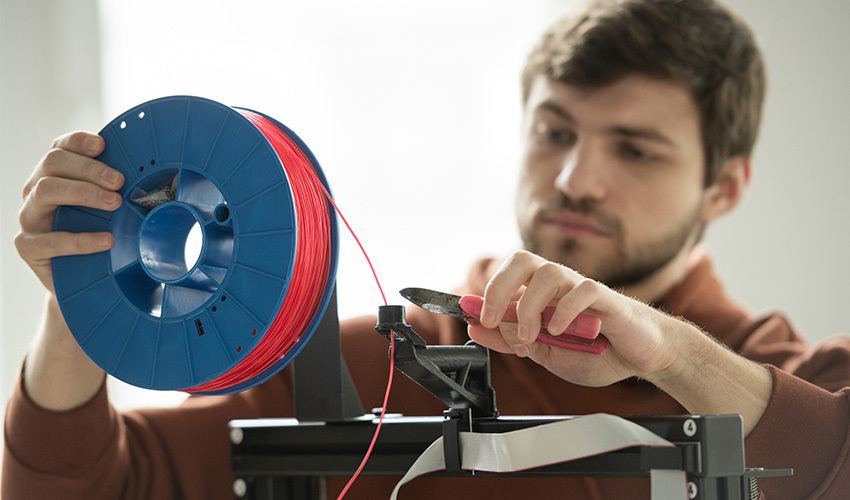

When you purchase a 3D printer, you’ll be adding another piece of equipment to your office space. That means you’ll need somewhere to put it. Once you start 3D printing, you’ll also need filament to print with it. With so many suppliers offering different filament, making the right decision can be challenging. We understand how frustrating it can be when a brand new printer produces poor results after using the same type of filament for 3-4 previous models. To help make the process a little easier, we have reviewed the best and worst options available on the market today.

What is 3D printing?

3D printing is the process of creating a three-dimensional physical object from a digital model. You can think of a 3D printer as a way to “print” an object layer by layer. Unlike traditional milling machines, 3D printers don’t work with “dies” but rather with “filaments”. The 3D printer will “draw” the desired shape by melting the filament and extruding it as a thin layer through a nozzle onto a build platform (the piece of material you’re printing on). The layer will solidify when it comes into contact with the build platform and the machine will continue to print the next layer. The whole process can be thought of as a continuous fabrication process.

3D Printing Filament Overview

If you had a 3D printer and a supply of filament, you could theoretically turn it into a “factory”. The amount of filament you could print would be limited only by the size of your build platform and the amount of filament available. 3D printers can print various materials including plastic, wood, leather, metal, and even food.

Filaments are produced in various forms including 3D printer filament, 3D printing filament, fused deposition modeling filament, and more. Because of the unlimited range of materials available, many consumers are interested in using their 3D printers to print out custom parts. However, even standard filament has its advantages; plastic filament is great for printable items that will be used in daily life like cups, figurines, and toys.

Best filament for 3D printing: ABS

ABS filament stands for “acrylonitrile butadiene styrene”. It is the best filament for printing most items. It is cheap, easy to clean, has good adhesion and wears well. ABS is a versatile material that can be used for almost any type of 3D printing project. It has excellent mechanical properties, making it the material of choice for 3D printing functional items like cell phones, tabletops, and home office equipment.

It has good heat resistance, making it a good choice for printing functional items like outdoor furniture, tools, and kitchenware. ABS has a Shore A hardness of approximately 70. This hardness makes it a good choice for printing decorative items like figurines, models, and furniture. It has excellent wear resistance and abrasion resistance. Therefore, it is the best material for printing durable items like toys, tools, and sporting equipment.

Runner Up: SLA filament

SLA filament, also known as photopolymer, is a liquid that can be 3D printed via SLA (stereo lithography) technology. SLA is a newer technology that uses light to create 3D models from a 2D drawing or photograph, unlike other 3D printing technologies that use an object as the model. Photopolymer SLA printing uses a liquid photopolymer to create a liquid model that can then be solidified into a 3D printed object. Photopolymer printing is considerably faster than other 3D printing technologies. Photopolymer 3D printing is also a great option for designers and artists who want to create custom or limited edition products at a low cost.

While photopolymer printing is a good option for large-scale production, it is not suitable for printing at home without a professional grade 3D printer. Photopolymer SLA printing can be used to create 3D models out of a variety of materials including ABS, PLA, and HIPS. The printing process itself is quite simple. First, the model is created in a 2D drawing or photograph. Then, a model is created in 3D from this 2D drawing. Once the model is created in 3D, the photopolymer is added to the printer head to produce the 3D printed object.

Worst filament for 3D printing: PC/ PET-G

PC and PET-G is a type of resin that works with 3D printers. They are the worst filament because they can create low quality prints and they are difficult to remove once printed. PC and PET-G are available in many different colors and they look like hard plastic. This filament works well for decorative and prototype items.

Sometimes, you can even print on PET-G edible items like ice creams and cakes. Unfortunately, PET-G is not suitable for most applications. The reason it is considered the worst filament is because when you print PET-G, it can come out as a low quality print. You can also see a lot of dust and residue on PET-G prints. PET-G resins are also difficult to remove from the prints.

Final Words

When it comes to 3D printing filament, there is a lot of confusion among consumers. It is difficult to choose the best filament for your 3D printer, and even more challenging to find a reliable vendor. With that in mind, there are a few things you can do to ensure you get the best possible results from your filament.

First, make sure you purchase from a reputable vendor. This will help you avoid low-quality filament while also providing you with the best customer support if you run into any issues. Next, decide how you wish to use your filament. It is important to keep in mind that 3D printer filaments are not interchangeable. You will need to find the right material for the type of project you wish to print with it.

3D filament is quite pricey, so you may want to consider purchasing two different filaments if you are unsure which one to use. This way, you can print with one before switching to the other if you are unhappy with the results.