This article covers everything you need to know about designing products for 3D printing. Designing for 3D printers is different from designing for other manufacturing methods, and it’s important to understand the differences if you want your product to succeed. Read on to learn more about how to design for 3D printing, from understanding what a good design looks like through CAD software and selecting the right materials through post-processing equipment.

3D Printing Basics

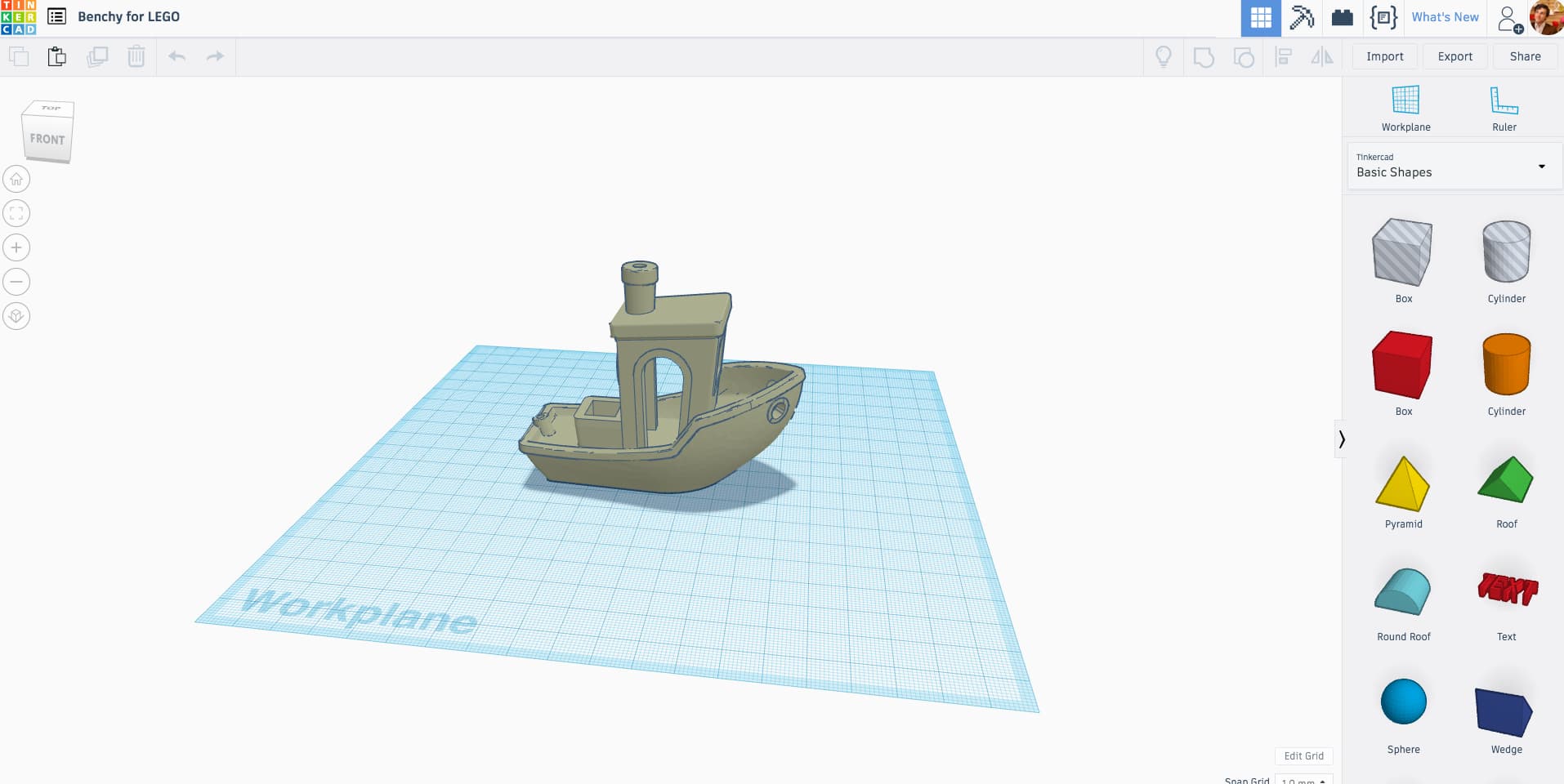

The first thing you need to know is how 3D printing works. 3D printing is a process that builds up a three-dimensional object layer by layer. The process starts with a 3D model in a CAD software, and a 3D printer “prints” this model layer by layer. This allows you to create virtually any shape or design that could be created with a computer.

There are several types of 3D printers, but all of them work on the same principle. The 3D printer takes a model that’s been created in CAD software and prints it layer by layer so that it assumes the shape of the original CAD model. All 3D printing technologies involve two main parts: a 3D printer, and a 3D model. The 3D printer is the part that creates the final product, while the 3D model is the CAD file that tells it what to print.

What is 3D Printing?

3D printing is the process of using a 3D printer to create a three-dimensional object layer by layer. The object can take virtually any shape or form imaginable. The process starts with a CAD model in a CAD software. This CAD model can be created by anyone whether a designer, engineer, or manufacturer. The CAD model, which is a set of instructions, tells the 3D printer what to print.

A 3D printing process involves two main parts: the 3D printer, and the 3D model. The 3D printer is the part that creates the final product, while the 3D model is the CAD file that tells it what to print. The CAD model could be created by anyone whether a designer, engineer, or manufacturer.

Different Types of 3D Printing

There are 3 main types of 3D printing: SLA (Stereolithography), FDM (Fused Deposition Modeling), and SLS (Selective Laser Sintering). SLA and FDM are both additive processes. In SLA, liquid plastic is cured layer by layer by the use of an ultraviolet light source and an image-sensing system. FDM printing uses a special type of thermal transfer process to print objects layer by layer. In SLS printing, a laser fuses together two different inks to create a solid object layer by layer.

CAD Software for Designing Products for 3D Printing

A great tool for designing products for 3D printing is Fusion 360, a cloud-based CAD software. The software is easy to use and has a wide range of functionalities for creating products for 3D printing. The easiest way to get started is by downloading the software for free for a 30-day trial. After the trial period, Fusion 360 costs $25 per month or $300 one time. The software lets you design products for 3D printing and export designs in several formats.

Selecting the Right Materials for 3D Printing

Most types of 3D printing use plastic as a material. Though most plastics are suitable for printing, you should keep in mind certain factors when selecting the right plastic for your 3D printing project. PLA is a safe, biodegradable plastic that’s commonly used.

It can be used for a number of projects, including food containers, toys, musical instruments, and electronics. ABS (Acrylonitrile-butadiene-styrene) is another type of plastic commonly used in 3D printing. It’s more durable than PLA and is perfect for outdoor projects.

Post-Processing Equipment for Printed Products

If you’re designing products that will be 3D printed, you’ll need to consider some post-processing equipment for printed products. The equipment is used to make the printed object smooth and to remove any imperfections in the design.

A heated print bed is commonly used for this purpose. A heated print bed is a metal plate that’s heated up with a heat gun to smooth out imperfections in the printed product. A ball mill is a post-processing tool used to remove any plastic particles or granules that didn’t adhere properly to the object during the process.

Conclusion

To design products for 3D printing, you need to understand the unique properties of the process. The process begins with a CAD model, and the CAD model can be created by anyone: engineers, designers, or manufacturers. The CAD model tells the 3D printer what to print. Once the 3D printer has created the design, it’s best to post-process the product to smooth out any imperfections.

There are several types of 3D printers, but all of them work on the same principle: the 3D printer takes a model and creates an object layer by layer. The design for the process should be created in CAD software. Once the design is created, it can be exported to several formats so that it’s ready for 3D printing.