3D printing and robotics have revolutionized the prototyping and manufacturing industry, providing new opportunities for businesses to create custom products and improve production efficiency. In this article, we will explore the advancements in 3D printing and robotics and how they are changing the face of prototyping and manufacturing.

3D Printing Advancements

3D printing, also known as additive manufacturing, is a process of creating a three-dimensional object by layering materials, such as plastic or metal, on top of each other. This technology has advanced significantly in recent years, providing new opportunities for businesses to create custom products and improve production efficiency.

Advanced Materials

Advancements in 3D printing have allowed for the use of a wide range of materials, including metals, ceramics, and even living tissue. This has opened up new possibilities for creating custom products and prototypes for various industries, including aerospace, healthcare, and automotive.

Enhanced Printing Speeds

Printing speeds have increased significantly in recent years, allowing for faster production times and improved efficiency. This has made 3D printing a viable option for mass production in certain industries, such as aerospace and healthcare.

Improved Accuracy

Advancements in 3D printing technology have also led to improved accuracy, allowing for the creation of complex and precise designs. This has made 3D printing a viable option for prototyping and manufacturing in industries where precision is essential, such as aerospace and medical.

Robotics Advancements

Robotics has also made significant advancements in recent years, providing new opportunities for businesses to improve production efficiency and reduce costs.

Collaborative Robots

Collaborative robots, also known as cobots, are robots that work alongside humans to perform tasks. These robots are designed to be safe and easy to use, allowing businesses to improve production efficiency and reduce costs while maintaining a safe work environment.

Autonomous Robots

Autonomous robots are robots that can perform tasks without human intervention. These robots are designed to operate in a wide range of environments and perform a variety of tasks, such as manufacturing, packaging, and transportation.

Advanced Sensors and Vision Systems

Advancements in sensor and vision technology have allowed for the creation of robots that can sense and respond to their environment. These robots can perform tasks with greater accuracy and efficiency, making them a valuable asset in industries such as manufacturing and logistics.

The Intersection of 3D Printing and Robotics

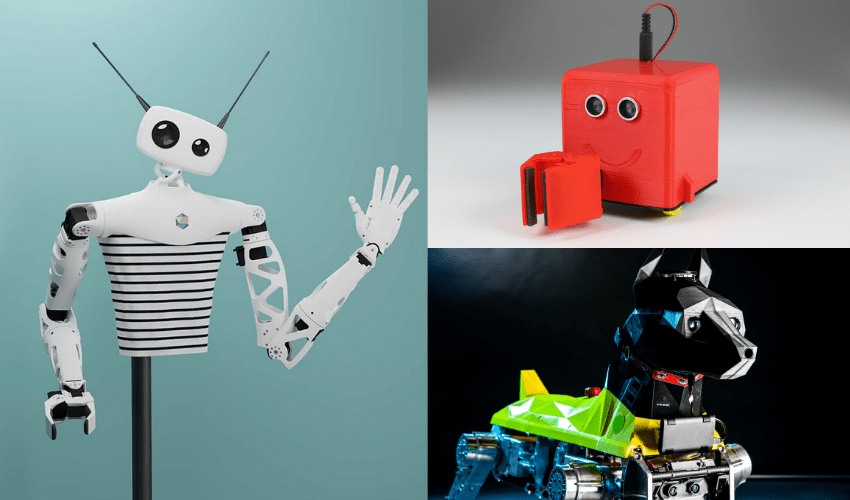

The intersection of 3D printing and robotics has created new opportunities for businesses to improve production efficiency and reduce costs. The use of 3D printing in robotics has allowed for the creation of custom parts and components, improving the accuracy and performance of robots.

Custom Parts and Components

The use of 3D printing in robotics has allowed for the creation of custom parts and components, improving the accuracy and performance of robots. This has allowed for greater flexibility in the design and manufacture of robots, making them more adaptable to a wide range of environments and tasks.

Reduced Costs

The use of 3D printing in robotics has also reduced costs, allowing for the creation of custom parts and components without the need for expensive tooling or moulds. This has made robotics more accessible to small and medium-sized businesses, allowing them to improve production efficiency and reduce costs.

Improved Performance

The use of 3D printing in robotics has also improved the performance of robots. Custom parts and components can be designed and manufactured with greater accuracy and precision, improving the overall performance of robots and reducing the risk of errors or malfunctions.

Applications of 3D Printing and Robotics

The advancements in 3D printing and robotics have created new opportunities for businesses in a wide range of industries. Here are some of the applications of 3D printing and robotics:

Aerospace and Defence

The aerospace and defence industries have been early adopters of 3D printing and robotics, using these technologies to create custom parts and components for aircraft and military vehicles. Robotics is also being used in the manufacturing and maintenance of aircraft and military equipment.

Healthcare

The healthcare industry has also been an early adopter of 3D printing and robotics, using these technologies to create custom prosthetics, implants, and medical devices. Robotics is also being used in surgical procedures and in the development of new treatments and therapies.

Automotive

The automotive industry has also been a major adopter of 3D printing and robotics, using these technologies to create custom parts and components for vehicles. Robotics is also being used in the manufacturing and assembly of vehicles, improving production efficiency and reducing costs.

Future Trends in 3D Printing and Robotics

As 3D printing and robotics continue to evolve, there are several future trends that are emerging in the prototyping and manufacturing industry. Here are some of the key trends to watch:

Integration with Artificial Intelligence (AI)

The integration of 3D printing and robotics with artificial intelligence (AI) is a growing trend in the industry. By incorporating AI technology, robots and 3D printers can become more autonomous, making decisions and adapting to changing environments in real-time.

Increased Use of Biomaterials

The use of biomaterials in 3D printing is a growing trend, particularly in the healthcare industry. By using living tissue and other biomaterials, researchers are able to create custom implants and prostheses that are more compatible with the human body.

3D Printing of Electronics

The use of 3D printing to create electronic components and circuits is a growing trend in the industry. This technology has the potential to revolutionize the electronics industry, allowing for the creation of custom circuits and components that are more efficient and cost-effective.

Expansion of Robotics in Service Industries

While robotics have traditionally been used in manufacturing and industrial environments, there is an increasing trend towards the expansion of robotics in service industries such as healthcare, retail, and hospitality. Robots are being developed to perform a variety of tasks, from assisting with patient care in hospitals to providing customer service in retail stores.

Development of Hybrid Manufacturing Systems

Hybrid manufacturing systems, which combine 3D printing and traditional manufacturing techniques, are becoming increasingly popular. These systems allow businesses to take advantage of the benefits of 3D printing while still utilizing traditional manufacturing techniques for certain components.

However, it’s important to note that while the advancements in 3D printing and robotics offer many benefits, there are also potential challenges and risks to consider. For example, the use of 3D printing and robotics may lead to job loss for some workers, and there are concerns about the impact of these technologies on the environment. It’s important for businesses to consider the ethical implications of using these technologies and to take steps to mitigate any potential negative impacts.

Conclusion

The advancements in 3D printing and robotics have transformed the prototyping and manufacturing industry, providing new opportunities for businesses to create custom products and improve production efficiency. The use of 3D printing in robotics has allowed for the creation of custom parts and components, reducing costs and improving performance. As these technologies continue to evolve and mature, we can expect to see even more innovation and growth in the industry. From the integration of AI to the use of biomaterials and the expansion of robotics into service industries, the future of 3D printing and robotics is bright, and it’s an exciting time to be working in this field.