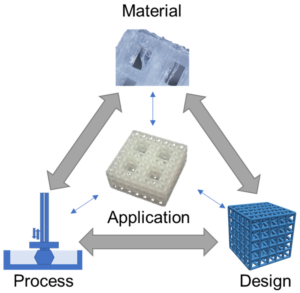

Materials science is a multidisciplinary field that explores the synthesis, processing, structure, properties, and performance of various materials. Over the years, advancements in materials science have led to the development of various materials with unique properties that have revolutionized industries such as aerospace, automotive, construction, and healthcare. One area where materials science has made a significant impact is in 3D printing, also known as additive manufacturing. In this article, we will discuss the advancements in materials science and their impact on 3D printing.

Advances in Polymer Materials:

Polymer materials are the most commonly used materials in 3D printing. In recent years, there have been significant advancements in polymer materials, including thermoplastics, thermosets, and elastomers. For example, carbon fiber reinforced polymers have been developed, which have high stiffness, strength, and toughness, making them ideal for use in the aerospace and automotive industries. There have also been advancements in the development of polymer composites with unique properties, such as flame retardancy and self-healing properties, which can be used in various applications.

Advances in Metal Materials:

Metal materials have also seen significant advancements in recent years. Traditionally, 3D printing with metals was limited to alloys such as titanium and stainless steel. However, there have been advancements in the development of new metal alloys, such as aluminum and nickel-based alloys, which have excellent mechanical properties and are ideal for use in the aerospace and medical industries. There have also been advancements in the development of metal composites, such as metal matrix composites, which have high strength and toughness, making them ideal for use in high-stress applications.

Advances in Ceramic Materials:

Ceramic materials have also seen significant advancements in recent years, particularly in the development of ceramic matrix composites. Ceramic matrix composites have excellent mechanical properties, such as high strength and toughness, and are ideal for use in high-temperature applications, such as in the aerospace and energy industries. Additionally, ceramic materials have excellent biocompatibility, making them ideal for use in medical implants.

Advances in Biomaterials:

Biomaterials are materials that are designed to interact with biological systems, such as cells and tissues. There have been significant advancements in the development of biomaterials for use in 3D printing, particularly in the medical industry. For example, there have been advancements in the development of biodegradable polymers, which can be used to create temporary implants that degrade over time as the body heals. There have also been advancements in the development of bioactive materials, such as hydroxyapatite, which can be used to create implants that bond with bone tissue.

Advances in Nanomaterials:

Nanomaterials are materials that have at least one dimension less than 100 nanometers. There have been significant advancements in the development of nanomaterials for use in 3D printing. For example, there have been advancements in the development of carbon nanotubes, which have excellent mechanical and electrical properties, making them ideal for use in the electronics and aerospace industries. There have also been advancements in the development of graphene, which has excellent mechanical properties and can be used to create lightweight and strong components.

Impact on 3D Printing:

The advancements in materials science have had a significant impact on 3D printing. By developing new materials with unique properties, 3D printing has become more versatile and can be used in a wider range of applications. For example, 3D printing with metal materials has become more common in recent years, allowing for the creation of complex metal parts with high precision. This has led to advancements in the aerospace and medical industries, where metal parts with complex geometries are often required.

Additionally, the advancements in biomaterials have had a significant impact on the medical industry. 3D printing has revolutionized the creation of medical implants, allowing for the creation of customized implants that fit a patient’s specific anatomy. This has led to faster recovery times and better outcomes for patients. Biodegradable polymers have also been used to create temporary implants that degrade over time, reducing the need for additional surgeries.

The use of nanomaterials in 3D printing has also had a significant impact on various industries. For example, the use of carbon nanotubes and graphene has led to the creation of lightweight and strong components, which are ideal for use in the aerospace and automotive industries. In the electronics industry, 3D printing with nanomaterials has led to the creation of high-performance electronic devices with unique properties, such as flexible and transparent displays.

Some potential future advancements in materials science that could impact 3D printing include the development of new materials with improved properties, such as higher strength, toughness, and biocompatibility. For example, researchers are currently exploring the use of materials such as spider silk and chitin, which have excellent mechanical properties and could be used in a variety of applications.

Another area of focus is the development of materials with improved sustainability. As 3D printing becomes more widespread, there is a growing concern about the environmental impact of the technology. Researchers are exploring the use of biodegradable materials and recycling techniques to reduce waste and increase sustainability.

In addition to new materials, advancements in 3D printing technology itself could also impact the field. For example, the development of multi-material and multi-color 3D printers could allow for the creation of even more complex and functional parts. Advances in software and design tools could also make it easier for designers to create and print customized parts for specific applications.

Overall, the impact of advancements in materials science on 3D printing is significant and will continue to drive innovation in a variety of industries. As researchers continue to push the boundaries of materials science, it is likely that we will see even more exciting developments in 3D printing in the future.

Conclusion:

In conclusion, the advancements in materials science have had a significant impact on 3D printing. By developing new materials with unique properties, 3D printing has become more versatile and can be used in a wider range of applications. The use of metal, ceramic, and biomaterials has revolutionized the creation of complex parts in industries such as aerospace, medical, and energy. The use of nanomaterials has also led to the creation of lightweight and strong components in industries such as automotive, aerospace, and electronics. As materials science continues to advance, it is likely that we will see even more advancements in 3D printing in the future, leading to new and innovative applications in various industries.