3D printing is a type of additive manufacturing. As the name suggests, it involves building up three-dimensional objects layer by layer. These objects can be made from any material that is possible to print, including metals and plastics. 3D printing is especially useful for making prototypes and short-run production runs of customized products to test market demand and reduce manufacturing costs.

3D printing has several different uses within manufacturing. For example, it can be used to produce molds for plastic parts or tooling for metal parts. It can also be used in conjunction with another manufacturing method called digital twins (or virtual factories). Digital twins are computer models of real-world factory operations such as assembly lines or stamp mills.

They are designed to help manufacturers see how their processes will look before they invest time and money in an actual factory build-out. These uses outlined here give you a good idea of the ways that 3D printing is put to use across various industries today. Let’s take a more detailed look at how it works and what kinds of industries it’s particularly useful for today

Why Is 3D Printing Important?

3D printing is a fast-growing technology that offers many benefits for businesses, especially manufacturers that can use it to produce custom parts or customize existing products. With 3D printing, you can produce any product according to your specifications with no minimum order quantities or minimum order quantities for custom products. It’s also a cost-effective alternative for production runs of one or a few hundred items.

Cost savings from using 3D printing is huge from both a financial and environmental perspective. By using 3D printing, you can reduce both capital and operating expenses while increasing productivity. Additionally, reduced shipping weight means lower shipping costs, meaning less overall cost of goods.

Types of 3D Printing

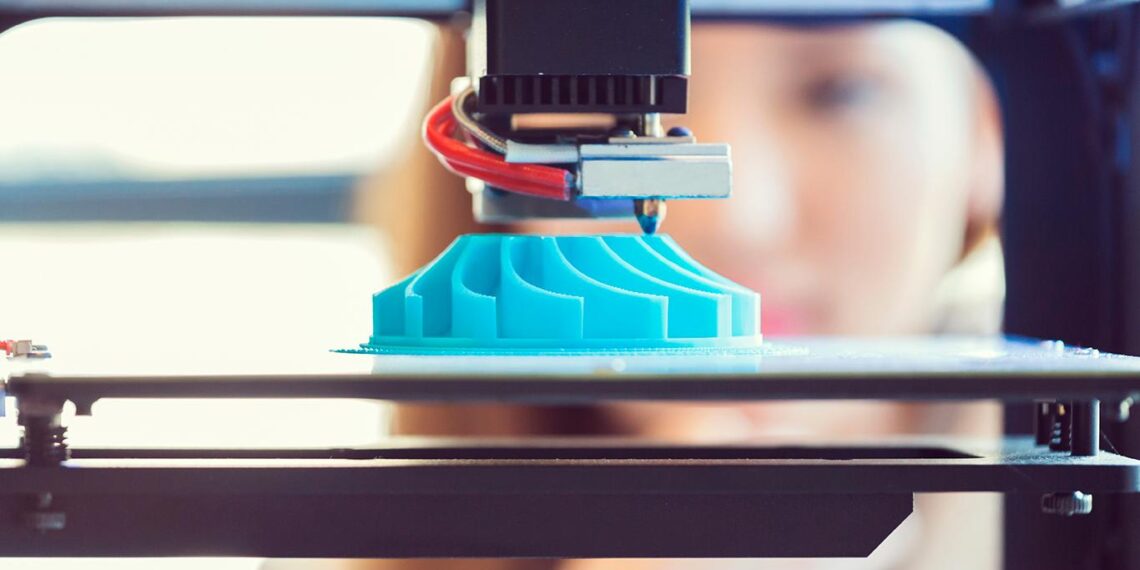

3D printers can print objects of just about any shape. Depending on the model, they can also print materials with varying levels of hardness, strength, and flexibility. Some can print in different materials like plastic, rubber, bronze, or silver. 3D printing is a form of additive manufacturing, which means that it involves creating three-dimensional shapes layer by layer.

A computer directs the printer to print each layer of the object so that each piece is built from the same material and using the same geometry. This means that the printer can create products that are identical to the original.

How 3D Printing Works?

As the printer moves around, it deposits a liquid material onto a build platform. The platform moves underneath the liquid layer, which builds up a thin, solid layer that can be the next layer of the product. The printer then moves to the next layer, and so on. Depending on the printer model, it can print one object or many.

The printer is programmed to deposit each layer at a precise speed to ensure the finished product is optimal in size and geometry. Slicing software is then used to remove the model from the printer’s build platform.

Applications of 3D Printing

3D printing has been used to make everything from house organs to jewelry. With this technology being so accessible for so long now, there are hundreds if not thousands of other products that can be made. Custom items – The ability to print custom products such as mugs, jewelry, and toys are particularly useful for makers and small businesses.

Even if you don’t have a specific need for custom items, the ability to create a mug with your company logo on it or a toy that is representative of your brand is a way to enhance the image of your company. Medical implants – The ability to create medical implants, including titanium implants and dental implants, is changing the way medical professionals practice.

With close to a million people in the United States suffering from either osteoarthritis or periodontitis, a way to replace damaged tissue or repair periodontal disease is of high value. Transportation – Auto and truck manufacturers are already exploring the potential of 3D printing to produce everything from a part to an entire car, including plastics and metals.

With the potential to drastically reduce the costs of producing parts, such as engines and transmissions, the car industry is expected to be one of the first industries to see significant benefits from 3D printing.

How to Learn About Manufacturing With a Workshop Session

You can get a great feel for the manufacturing side of 3D printing by visiting a production facility and participating in a workshop session. You’ll get a chance to see the tools and equipment that manufacturers use, along with the types of parts they make.

You can also ask the instructors about any trends or new technologies that are impacting your industry. During the workshop, you’ll be shown how a process works and how these parts are used in the real world. Additionally, you’ll gain an understanding of the materials and processes that go into manufacturing products.

Next Steps

If you’re interested in 3D printing but want to learn more, attend one of the workshops. Another way to get more information is to attend a live event, such as an industry conference or trade show. At these events, you can meet manufacturers who are using 3D printing, ask them questions, and learn more about the technology.