Robots are replacing humans in manufacturing.

Robots are replacing humans in manufacturing. They’re more accurate, consistent and efficient than humans. They can work 24/7 with no downtime or sick days (except when they break down). Robots don’t need to be trained; they just do what they’re programmed to do.

The rise of technology and automation

The rise of technology and automation is a key component of the future of manufacturing. Robots are already being used in many manufacturing processes, from simple tasks like picking up parts on an assembly line to more complex tasks such as welding and painting. Robots are cheaper than humans, can work around the clock without getting sick or taking vacations (though they’re also not allowed to drink alcohol), and don’t need breaks during long shifts like humans do!

The use of robotics will continue to increase as more companies invest in this technology. As robots become more common in our society, it may seem strange that we haven’t seen more automation at home yet–but don’t worry: Even though it seems like there’s never enough time when you’re busy trying not only to keep up with work but also to spend quality time together with family members too!

The ability to monitor and react to data in real time

As we become increasingly aware of the ability to monitor and react to data in real time, the future of manufacturing companies is full of potential. A huge amount of data is being gathered from many different sources, including sensors on machines, GPS tracking devices and even people who wear fitness trackers. This information can be analysed in real time to make better decisions about how best to run production lines or improve efficiency by identifying bottlenecks in production processes.

Industrial robots are transforming the workplace

The use of industrial robots is increasing in the manufacturing industry, with companies using them to automate repetitive tasks. Robots can be programmed to perform complex movements and make products that humans cannot make by hand. They are also faster than humans, so they don’t get tired working long hours on a daily basis.

While robots have been around for decades, their usefulness has increased dramatically over time due to new technology innovations like artificial intelligence (AI) and machine learning algorithms developed by software companies like Google or Facebook which provide automated solutions for certain tasks without requiring human intervention every time it’s needed.

The Internet of Things (IoT) is changing the way we live and do business

The Internet of Things (IoT) is changing the way we live and do business. IoT is the network of physical objects embedded with electronics, software, sensors, and connectivity to enable these objects to collect and exchange data. The IoT phenomenon is global in scale as there are millions of connected devices per day worldwide. IOT is a very important aspect to keep note of when we think about the future of manufacturing.

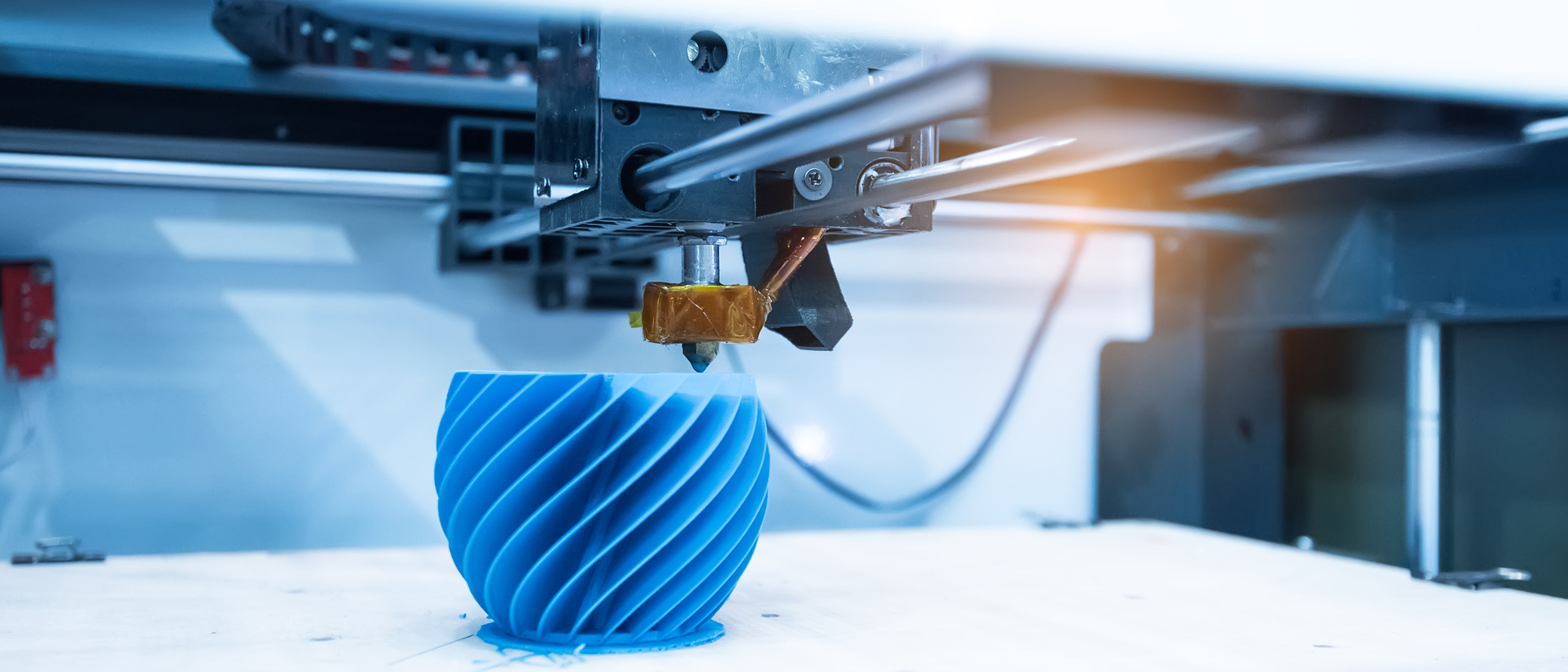

3-D printing is making manufacturing more efficient

3-D printing is a type of additive manufacturing that uses a machine to create physical objects from digital designs. The process involves building up layers of material, which can include plastics, metals or other materials. 3-D printers are used in many industries, including aerospace and automotive manufacturing; healthcare; toys; architecture; art; fashion/textiles and food processing. This innovation is helping companies to cut down costs when it comes to processes like prototyping and testing and is going to play a major role in determining the future of manufacturing.

The manufacturing industry is at a unique point in history.

The manufacturing industry is at a unique point in history. It has been through many changes over the past century, but recent developments are changing how we think about manufacturing and what it can do for businesses. The first change is that the traditional manufacturing model is shifting from physical production to digital production. This shift allows companies to streamline their operations, increase efficiency, and reduce costs by using new technology like 3D printing or robotics instead of human workers. It also opens doors for small businesses who may not have access to advanced machinery due to size or location restrictions (such as in rural areas).

The future of manufacturing will look very different than it does today

The future of manufacturing will be very different than it is today. It will be more efficient, more affordable and have a greater impact on the environment–all while providing an inclusive experience for workers and consumers alike.

The shift towards a digital economy has led to an increasing demand for automation in production processes. Digital technologies are being used to create customised products at scale that require fewer resources than traditional methods do; however this technology has only been adopted by large companies so far due to its high cost and complexity associated with adoption by small businesses or individuals. As such, less advanced countries continue investing heavily into traditional manufacturing methods like assembly lines because they believe these methods offer them better opportunities for growth over time rather than adopting new technologies which could disrupt their industry altogether.

Human workers and robots working together is an exciting new development

The idea of human workers and robots working together is an exciting new development. Robots can perform repetitive tasks that humans are not suited to do, such as assembly or packaging. Humans are better at creative tasks such as designing and programming, but these roles are changing very quickly with the rise of AI technology.

Robots have already been used in manufacturing for decades; however, they have mostly been confined to factories where they work autonomously on certain tasks under supervision from humans who monitor their progress. In recent years there has been growing interest in using robots for non-routine work around the plant or office environment as well as autonomous vehicles that drive themselves without human intervention (eVTOLs).

The future of manufacturing and its impact on traditional production methods

The future of manufacturing is an exciting new development. It’s a combination of human workers and robots working together to create a product, which can be anything from a smartphone to an aeroplane. This is what we call the “future of manufacturing” or FORM for short.

The key element here is that there will be no distinction between the two types of machines: human workers and mechanical ones are both involved in creating products from raw materials. The reason why this makes sense is because we’ve been able to automate many tasks that previously required manual labour–for example, packing boxes into shipping containers or putting together cars using 3D printers instead of humans who had to manually weld pieces together (or use rivets).

In fact, some people believe that artificial intelligence (AI) technology will eventually replace most jobs around the world by 2025 due to its ability to do complex tasks quickly without needing any training whatsoever!

Conclusion

The future of manufacturing has been a topic of discussion for decades. The rise of technology and automation in the workplace has changed the way we live and do business, but it’s not just about making things better–it’s also about creating new jobs and opportunities for workers.