The Role of 3D Printing in the Medical Field and the Creation of Prosthetics

The development of 3D printing technology has brought significant advancements to the field of medicine, particularly in the creation of prosthetics. 3D printing allows for the creation of complex, customized prosthetic devices that are both functional and aesthetically pleasing. In this article, we will explore the various ways in which 3D printing has impacted the medical field and the creation of prosthetics.

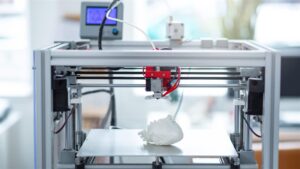

Introduction to 3D Printing

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by adding successive layers of material on top of each other. This technology has been around for several decades but has only recently gained popularity due to advancements in materials science and computing power.

In the medical field, 3D printing has been used to create a wide range of devices, including implants, surgical instruments, and prosthetics. The process of creating these devices typically involves using computer-aided design (CAD) software to create a 3D model of the object. The 3D printer then uses this model as a guide to create the physical object.

Advantages of 3D Printing in the Medical Field

One of the main advantages of 3D printing in the medical field is its ability to create customized devices. Traditional manufacturing methods rely on mass production, which means that each device is identical to the others. With 3D printing, however, each device can be customized to meet the unique needs of the patient. This is particularly important in the creation of prosthetics, where a customized fit is essential for the device to function properly.

Another advantage of 3D printing is its ability to create complex geometries. Traditional manufacturing methods often require multiple parts to be assembled together to create a complex object, which can lead to weak points and potential failure. With 3D printing, however, complex geometries can be created in a single piece, which results in a stronger and more durable device.

Additionally, 3D printing can significantly reduce the time and cost of creating medical devices. Traditional manufacturing methods often require expensive tooling and specialized machinery, which can take weeks or months to set up. With 3D printing, however, the device can be created in a matter of hours or days, and there is no need for expensive tooling.

The Role of 3D Printing in the Creation of Prosthetics

Prosthetics are artificial devices that are used to replace a missing limb or body part. Traditional prosthetics are often made from materials such as metal or plastic and are designed to fit a range of patients. This can lead to discomfort and difficulty using the device, as well as a lack of customization to the patient’s individual needs.

3D printing has revolutionized the field of prosthetics by allowing for the creation of customized devices that are tailored to the patient’s specific needs. This includes the shape and size of the device, as well as the materials used to create it. 3D printing can also create prosthetics with intricate designs that are both functional and aesthetically pleasing.

One of the main advantages of 3D-printed prosthetics is their low cost. Traditional prosthetics can cost thousands of dollars, which can be a barrier for many patients. With 3D printing, however, the cost of materials is significantly lower, and there is no need for expensive tooling or specialized machinery. This makes 3D-printed prosthetics a more accessible option for patients who may not have access to traditional prosthetics.

Another advantage of 3D-printed prosthetics is their lightweight and comfortable design. Traditional prosthetics can be heavy and bulky, which can make them uncomfortable for the patient to wear for long periods of time. 3D-printed prosthetics, on the other hand, can be designed to be lightweight and comfortable, which improves the patient’s overall quality of life. This is particularly important for children who may need to wear the prosthetic device for extended periods of time.

3D printing has also allowed for the creation of prosthetics with more advanced functionality. For example, 3D-printed prosthetics can incorporate sensors and other electronic components that allow the patient to control the device using their muscles or other movements. This type of technology is still in the early stages of development, but it has the potential to significantly improve the functionality of prosthetic devices in the future.

In addition to the creation of prosthetic devices, 3D printing has also been used to create models for surgical planning. Surgeons can use 3D-printed models to plan complex procedures, such as organ transplants, which can improve the accuracy and success of the surgery.

Challenges of 3D Printing in the Medical Field

While 3D printing has many advantages in the medical field, there are also some challenges that need to be addressed. One of the main challenges is the need for rigorous testing and regulation to ensure that the devices are safe and effective. 3D-printed medical devices are still a relatively new technology, and there is still much that is unknown about their long-term effects.

Another challenge is the need for specialized training and expertise in 3D printing technology. While 3D printing has become more accessible in recent years, there is still a significant learning curve involved in using the technology effectively.

Conclusion

In conclusion, 3D printing has had a significant impact on the medical field, particularly in the creation of prosthetic devices. The technology allows for the creation of customized devices that are both functional and aesthetically pleasing, and it has significantly reduced the cost and time of creating medical devices. While there are still challenges that need to be addressed, 3D printing has the potential to revolutionize the field of medicine in the coming years.