Introduction

There are many benefits to using 3D printing in the creation of prosthetics, assistive devices and other medical supplies. This technology can be used to create custom prosthetics that fit individual needs, as well as items such as artificial limbs that are made with a variety of materials including plastics, metals and even wood. The process for creating these devices is relatively simple; only requiring a few steps to go from concept to finished product.

What is 3D printing in the creation of prosthetics

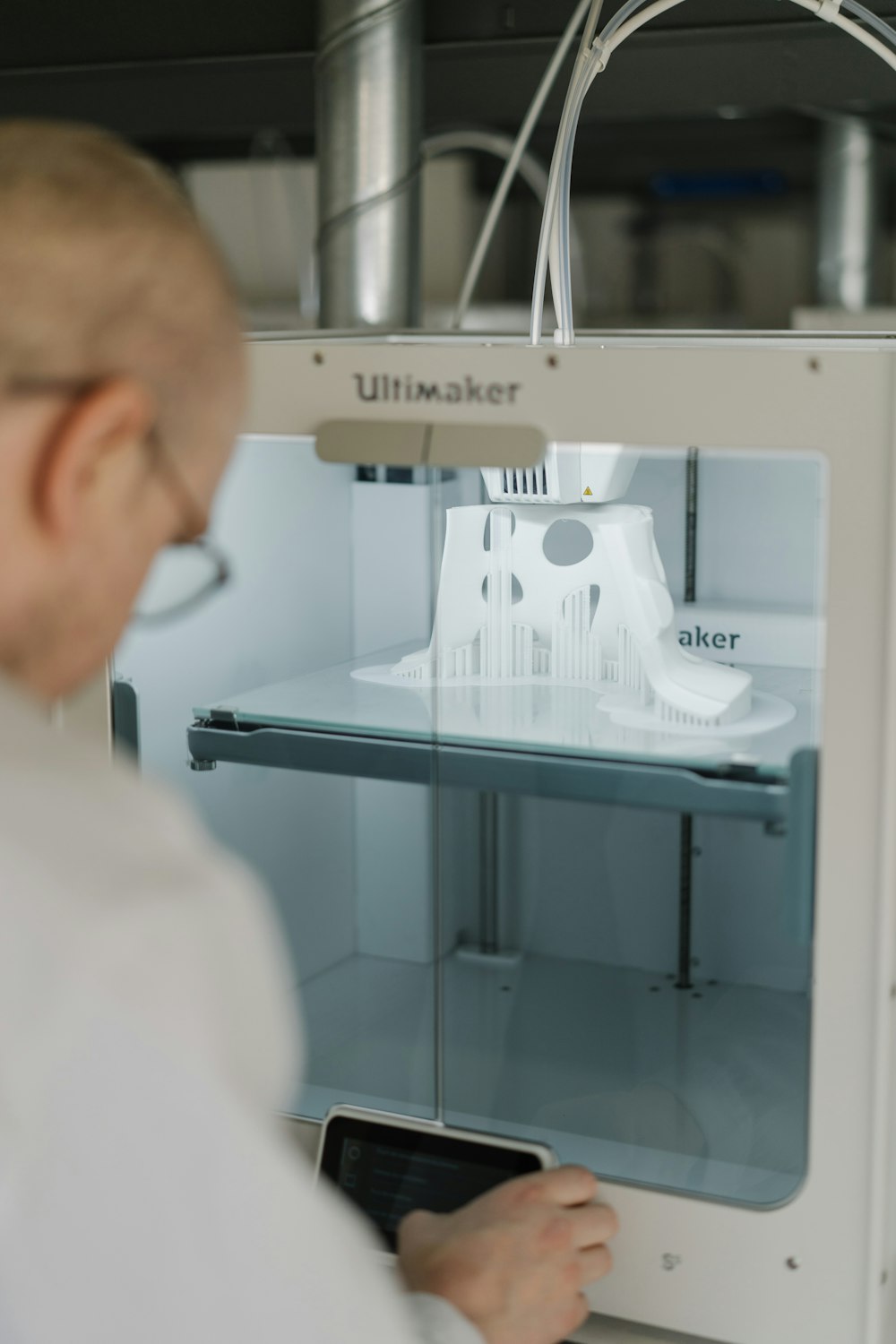

3D printing is the process of creating a three-dimensional object from a digital model. The technology can be used to create prototypes, models or even finished products. To do this you will need to have access to the right software and hardware which you can purchase online or at your local store.

What are some of the benefits of using 3D printing in the creation of prosthetics

3D printing in the creation of prosthetics and assistive devices is a more affordable option than traditional manufacturing. It’s also faster, as you can create your product in less time than it would take to make the same product through traditional methods. The ability to create custom products is another benefit of 3D printing: you can design something specific to meet your needs, rather than having someone else dictate what they want. The final product will fit perfectly and look exactly how you envisioned it when designing it!

How is this technology being used right now?

There is a big role of 3D printing in the creation of prosthetics and assistive devices. Prosthetic limbs are made using 3D printers, which can be customised by the user in order to fit their needs. For example, if you have an amputated leg or arm that was replaced with a metal or plastic prosthetic–the body part itself will be constructed using precision-milled steel and other materials. The end product looks just like your original limb did before it was lost; however, this time around there’s no chance of infection from bacteria spreading through dirt on your skin!

The role of 3D printing in the creation of prosthetics and assistive devices.

3D printing is a process of creating three-dimensional models by using special equipment to deposit layer upon layer of material until a desired shape is achieved. It can be used for many different purposes, such as custom prosthetics and assistive devices.

3D printing in the creation of prosthetics and assistive devices is not entirely new as it has been used to make custom made prosthetic limbs since the 1990s, but it wasn’t until recently that doctors were able to create high-performance artificial limbs using this technology. Today there are hundreds of companies around the world offering innovative solutions for people with disabilities or amputations who need new hands or feet, among other things.

3D Printing can have a big impact on the world.

3D printing in the creation of prosthetics and assistive devices can have a big impact on the world. As you know, 3D printers are already being used to create prosthetic limbs for people who have lost their limbs due to accidents or medical conditions. They’re also being used for other purposes, such as creating parts that can be used in medical devices such as heart pumps and pacemakers.

3D printing of prosthetics and assistive devices began to gain traction in the late 2000s.

3D printing in the creation of prosthetics and assistive devices began to gain traction in the late 2000s. The first reason for this is that 3D printing has become much more accessible, but another reason is that people have started to wonder if this technology could be used for prosthetics. In fact, it was not long before medical professionals started experimenting with how they could use 3D printed parts on patients who had lost limbs or other body parts due to accidents or disease.

It wasn’t long before some companies started offering their own products based on these new technologies, which we now know as “3D printed prosthetic hands.” These devices are made out of plastic materials like PLA (polylactic acid), Nylon (polyamide), ABS (acrylonitrile butadiene styrene) and others–and they’re designed with specific functions in mind: one might have better grip strength than another because its fingers are thicker than those on others; another might have longer fingers so it can reach further into space without hitting anything along its path there!

3D printing is used to produce prosthetic limbs.

3D printing in the creation of prosthetics and assistive devices is gaining popularity. It can be used as a way to create custom prosthetics, or it can be used to create standard-issue prostheses. Technology has helped people with disabilities have more freedom than ever before. For example, a person who lost their arm in an accident may use a 3D printer to make his or her own new arm out of plastic parts that were designed by doctors and engineers.

In this case, the patient is able to customise the dimensions of their new limb so that it fits perfectly around his or her body, which gives him/her much more control over how he/she moves around and interacts with others as well as increases overall mobility in daily living activities such as walking or climbing stairs without assistance from others like family members or friends who might need assistance getting things done instead!

3D printing can be used to produce custom prosthetics.

3D printing in the creation of prosthetics and assistive devices is great for producing custom prosthetics. A 3D-printed prosthetic is a type of artificial limb that has been constructed by using a variety of different materials such as plastic or metal, depending on the patient’s needs and preferences.

The body part being replaced (such as an arm) is scanned and then recreated on a computer with virtual models so that it looks exactly like the original one did before it was lost or damaged. This process has helped many people regain their independence from wheelchairs in order to walk again at home without assistance from others around them; however there are still some limitations associated with these new devices due to their size as well as other factors such as cost and availability.”

3D printing can be used to produce assistive devices.

3D printing can be used to create custom devices. For example, a child who has lost their hands may need a prosthetic hand that is customised for their needs. A 3D printed device could be customised with different functionality and colour choices so that it fits in with the child’s individual style and preferences. The same goes for adult patients who want to wear a 3D printed prosthetic hand instead of an off-the-shelf model.

3D printing in the creation of prosthetics and assistive devices can also be used for devices such as wheelchairs or walkers that help people walk again after breaking their hips or knees (or other injuries). Once again, these types of assistive devices would need to be tailored specifically based on each patient’s needs–and there are no rules when it comes to this kind of customization!

Conclusion

3D printing in the creation of prosthetics is a fast-growing technology that has the potential to revolutionise the way we produce prosthetics and assistive devices. By creating custom limbs, people with disabilities can regain more freedom than ever before. The possibilities are endless when it comes to 3D printing of prosthetics and assistive devices; there are many things that can be done with this technology that will make life easier for everyone involved!