3D printing, also known as additive manufacturing, has revolutionized the manufacturing industry in recent years. This technology has transformed the way products are designed and produced, and the fashion and accessory industry is no exception. 3D printing has brought a new level of creativity and customization to the industry, and its impact can be seen in various areas, from design to production and distribution.

Design and Creativity

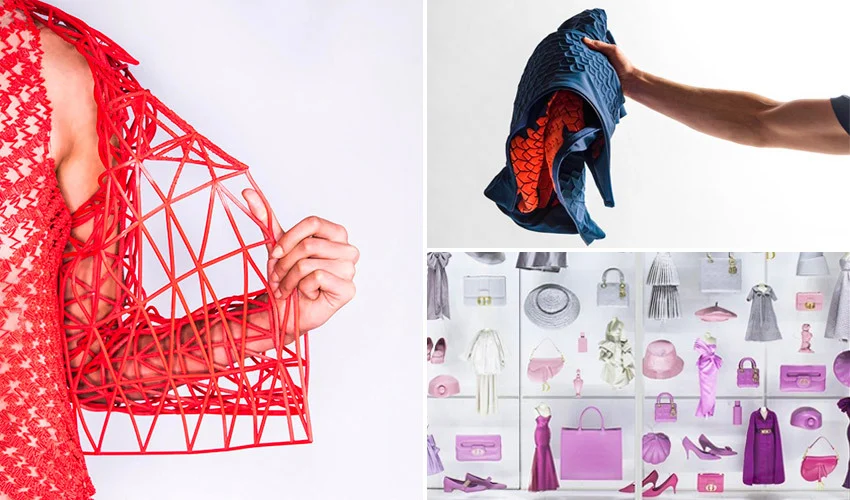

The fashion and accessory industry is all about creativity and design, and 3D printing has allowed designers to push the boundaries of what is possible. With 3D printing, designers can create complex shapes and intricate designs that were once impossible to produce using traditional manufacturing methods. This has led to a whole new level of creativity, and designers are now able to experiment with different shapes, patterns, and textures that were not possible before.

Furthermore, 3D printing has made it easier for designers to create prototypes of their designs. Instead of having to wait weeks or months for a prototype to be produced, designers can now create a 3D model and print it out in a matter of hours. This has made the design process faster and more efficient, allowing designers to make changes to their designs and iterate more quickly.

Customization

One of the biggest advantages of 3D printing is customization. With traditional manufacturing methods, producing custom-made products can be expensive and time-consuming. However, with 3D printing, customization is much easier and more cost-effective.

3D printing allows designers to create custom-made products for individual customers, and this has led to the rise of bespoke fashion and accessories. Customers can now work with designers to create a product that is tailored to their specific needs and preferences, whether it’s a piece of jewellery or a pair of shoes. This has created a new level of personalization in the industry, and customers are willing to pay a premium for customized products that are unique to them.

Sustainability

The fashion industry has long been criticized for its impact on the environment, and 3D printing has the potential to change this. With traditional manufacturing methods, there is often a lot of waste generated during the production process. However, 3D printing is a more sustainable option as it only uses the materials needed to create the product, reducing waste and minimizing the environmental impact.

Moreover, 3D printing allows for on-demand production, which means that products are only produced when they are needed. This reduces the need for excess inventory, which can be costly and environmentally harmful. By producing only what is needed, the fashion and accessory industry can reduce its carbon footprint and become more sustainable.

Challenges

Despite its many advantages, 3D printing also presents some challenges for the fashion and accessory industry. One of the biggest challenges is the cost of 3D printers and materials. While the cost of 3D printers has come down in recent years, they are still expensive compared to traditional manufacturing equipment. Additionally, the cost of materials for 3D printing can be high, particularly for high-quality materials such as metals and ceramics.

Another challenge is the speed of 3D printing. While 3D printing is faster than traditional manufacturing methods for creating prototypes, it is still relatively slow when it comes to producing large quantities of products. This means that 3D printing may not be a practical option for mass production, at least not yet.

One area where 3D printing is already making an impact is in the production of accessories, such as jewellery and eyewear. These products often require intricate designs and custom sizing, which can be difficult and costly to produce using traditional methods. However, 3D printing allows for more precise and efficient production of these products, making them more accessible to consumers.

Another area where 3D printing is being used is in the creation of unique and innovative fabrics. By using 3D printing technology to create custom fabrics, designers can create garments that are unlike anything that has been seen before. This has the potential to change the way we think about fashion and could lead to a new era of sustainable and personalized clothing.

Another way that 3D printing is changing the fashion and accessory industry is through the creation of wearable technology. 3D printing allows designers to create products that integrate technology seamlessly into clothing and accessories. For example, 3D printed jewellery can incorporate sensors or tracking devices, allowing wearers to track their fitness goals or monitor their health. This has the potential to revolutionize the way we think about fashion and technology and could lead to a new era of personalized and interactive clothing.

In addition to the impact on the design and production process, 3D printing is also changing the way products are distributed. With traditional manufacturing methods, products are produced in large quantities and distributed to retailers around the world. However, 3D printing allows for on-demand production, which means that products can be produced and distributed locally. This has the potential to disrupt the traditional supply chain and create a more decentralized and sustainable fashion industry.

Moreover, 3D printing is also being used to produce sustainable materials for fashion and accessories. For example, 3D printing can be used to create biodegradable materials that can be used to make products that are environmentally friendly. This has the potential to reduce the fashion industry’s impact on the environment and create a more sustainable future.

Conclusion

Overall, the impact of 3D printing on the fashion and accessory industry has been significant. This technology has allowed designers to push the boundaries of creativity and has made customization more accessible to customers. Additionally, 3D printing has the potential to make the industry more sustainable by reducing waste and minimizing the environmental impact.

While there are still some challenges to overcome, such as the cost of equipment and materials and the speed of production, the future of 3D printing in the fashion and accessory industry looks promising. As the technology continues to advance and become more affordable, we can expect to see more widespread adoption of 3D printing in the industry.