3D Printing and Sustainability

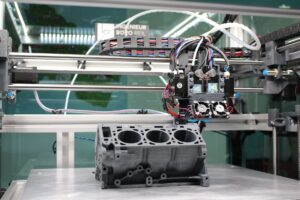

3D printing has the potential to revolutionize the manufacturing industry, offering greater flexibility, speed, and customization. However, as we move forward into the future, it is important to consider the environmental impact of 3D printing and to explore innovative approaches and practices that promote sustainability. In this article, we will explore some of the ways in which 3D printing and sustainability can intersect, including eco-friendly materials, sustainable processes, and circular economy models.

Eco-Friendly Materials

One of the key ways in which 3D printing and sustainability intersect is through the use of eco-friendly materials. Traditional manufacturing methods often rely on materials that are not renewable, such as plastic, metal, and other non-biodegradable materials. However, 3D printing offers the possibility of using more sustainable materials, such as biodegradable plastics, recycled materials, and even organic materials like wood and bamboo.

For example, some companies are using recycled plastic to create 3D printed objects, reducing waste and promoting sustainability. Others are using biodegradable materials like PLA (polylactic acid), which is made from renewable resources like corn starch and sugarcane, to create 3D printed objects that can break down naturally over time. These materials offer a more sustainable and eco-friendly alternative to traditional manufacturing materials, reducing the environmental impact of 3D printing.

Sustainable Processes

Another way in which 3D printing and sustainability intersect is through the use of sustainable processes. Traditional manufacturing methods often rely on energy-intensive processes that contribute to greenhouse gas emissions and other environmental issues. However, 3D printing offers the possibility of using more sustainable processes, such as renewable energy sources and closed-loop systems.

For example, some 3D printing facilities are powered by renewable energy sources like solar and wind power, reducing the carbon footprint of the manufacturing process. Others are using closed-loop systems that recycle materials and reduce waste, promoting a circular economy model that is more sustainable and eco-friendly.

Circular Economy Models

One of the most innovative approaches to 3D printing and sustainability is the use of circular economy models. The circular economy is a model of production and consumption that emphasizes the use of renewable resources, minimizes waste and pollution, and creates a closed-loop system that is sustainable over the long term.

In the context of 3D printing, this means using recycled materials, creating products that are designed for disassembly and reuse, and promoting a culture of repair and maintenance. For example, some companies are using 3D printing to create replacement parts for products that would otherwise be discarded, reducing waste and promoting a circular economy model. Others are using 3D printing to create products that can be easily disassembled and recycled at the end of their life cycle, reducing the environmental impact of the manufacturing process.

In addition, some companies are using 3D printing to create products on demand, reducing the need for large-scale manufacturing and promoting a more sustainable and efficient model of production. This approach can also reduce the environmental impact of transportation, as products can be produced locally and on demand, reducing the need for long-distance shipping and reducing the carbon footprint of the manufacturing process.

In addition to these approaches, there are also other innovative practices that can be used to promote sustainability in 3D printing. For example, some companies are using 3D printing to create products that are designed to be repaired and maintained, rather than replaced. This approach promotes a culture of repair and reduces the environmental impact of manufacturing by reducing waste and promoting a circular economy model.

Another approach is to use 3D printing to create lightweight products that require less energy to transport. This can reduce the carbon footprint of transportation and promote a more sustainable and efficient model of production. Additionally, some companies are using blockchain technology to track the environmental impact of 3D printing, promoting transparency and accountability in the manufacturing process.

While there are many innovative approaches and practices that can be used to promote sustainability in 3D printing, there are also challenges and considerations to keep in mind. For example, there are still limitations in terms of the materials that can be used in 3D printing, as well as challenges around intellectual property and quality control.

In addition, there is a need for greater awareness and education around the environmental impact of 3D printing, both among consumers and manufacturers. By promoting a culture of sustainability and promoting eco-friendly practices, we can ensure that 3D printing is used in an ethical and responsible manner.

As the field of 3D printing continues to evolve, there is also a need for greater collaboration and cooperation among manufacturers, policymakers, and consumers. By working together, we can ensure that 3D printing is used in a responsible and sustainable manner, promoting a more environmentally conscious approach to manufacturing.

In addition, there is a need for greater investment in research and development to explore new materials and processes that are more sustainable and eco-friendly. By investing in innovation and advancing the field of 3D printing, we can create new opportunities for sustainable and environmentally conscious manufacturing.

Overall, 3D printing and sustainability are two concepts that are closely intertwined, offering the potential to revolutionize the manufacturing industry while also promoting a more sustainable and environmentally conscious future. By using innovative approaches and practices, we can ensure that 3D printing is used in a responsible and sustainable manner, promoting a more sustainable and environmentally conscious approach to manufacturing.

Conclusion

3D printing offers the potential to revolutionize the manufacturing industry, offering greater flexibility, speed, and customization. However, as we move forward into the future, it is important to consider the environmental impact of 3D printing and to explore innovative approaches and practices that promote sustainability.

By using eco-friendly materials, promoting sustainable processes, and embracing circular economy models, we can create a more sustainable and eco-friendly future for 3D printing and manufacturing. With careful planning and consideration, 3D printing has the potential to transform the way we approach product design and manufacturing, while also promoting a more sustainable and environmentally conscious future.